Through Tubing Evaluation and

Verification for Rigless P&A Trials

OVERVIEW

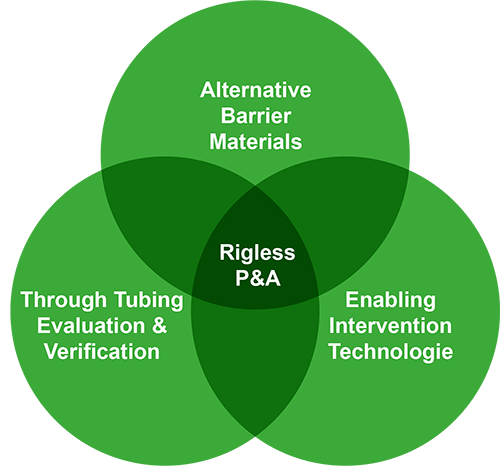

Rigless P&A has potential to significantly reduce time during well decommissioning and thereby contribute to both cost and emissions reduction. The objective of this ISP programme is to secure field trials for logging tools that provide solutions to evaluate the condition of existing barrier elements in the well or to verify the performance of barriers installed in the well during rigless abandonment programmes.

Securing access to log wells in the field will demonstrate tool deployment and provide “real well” data to accelerate development of advanced data analysis and interpretation capability. Both of these are key steps to building confidence among well operators to encourage adoption of the technologies and to providing track record to justify the choice of technology in P&A programmes to regulators.

Led by Repsol SINOPEC Resources UK, the programme is supported by industry and the Net Zero Technology Centre. The initial focus will be on Through Tubing Cement Evaluation technology but the scope will encompass barrier element verification and other through tubing services that support rigless P&A.

Quicklinks

Through Tubing Evaluation and Verification

Abandonment barriers can include multiple elements including annular cement behind casing strings. Assessing the condition of cement behind casing to determine its suitability as a well barrier element is a key step in the design and placement of permanent well barriers during P&A. In some cases the condition of cement behind multiple casing strings needs to be assessed.

Ideally, the condition of the cement should be evaluated as part of the well decommissioning process, however, operators often rely on cement evaluation logs run during well construction. Historically, cement bond logs were often only run when problems arose during primary cementing. Where logs do exist there is uncertainty regards any deterioration in the quality of the cement barrier during the well life cycle. In the absence of cement evaluation logs operators can using industry guidelines based on “rules of thumb” regarding the minimum length of cement column present to estimate if it is likely that adequate good quality cement exists to function as a well barrier. However, for many legacy wells, information that is required to estimate TOC has high uncertainty either due incomplete data recording initially or missing drilling records (e.g. during change of field ownership).

To evaluate cement quality behind casing with conventional logging tools requires having to cut and recover tubing to access the casing string, adding significant rig time and technical complexity to well decommissioning operations. Through tubing cement evaluation technology removes that requirement and in doing so can allow the evaluation to be made off of the rig schedule using lower cost assets or as part of campaign to benefit from shared mobilisation costs.

Removing the requirement to recover the tubing string to evaluate cement quality also opens the door to the use of other through tubing P&A technologies. These include deployment of alternative barrier materials and barrier verification technologies in addition to “enabling technologies” to remove control lines, remediate damaged cement, tubing severance. The ability to leave the tubing in place as part of a competent abandonment barrier will facilitate the use of smaller footprint assets to support rigless abandonment with potential to reduce time and hence cost and emissions.

In addition to the potential to reduce operational emissions during well decommissioning, through tubing evaluation and verification capability could also support wider ‘net zero’ and energy transition efforts e.g. assessing the containment risk of wells in depleted fields for Carbon or Hydrogen storage projects.

Multi String Varrier Evaluation Technologies

Technology developers are combining advanced sonic array measurements with established ultrasonic imaging to evaluate barriers behind multiple strings (tubing/casing or casing/casing). Multi-sensor platforms are being developed which combine neutron, x-ray, electromagnetic and ultrasonic logging technologies. Developers are also working on the application of Artificial Intelligence and Machine Learning to enhance imaging and log interpretation.

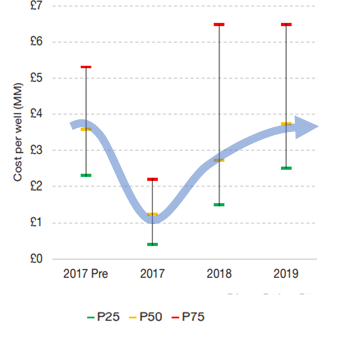

Well Decommissioning Cost Challenge

Well decommissioning accounts for circa 45% of the total UKCS decommissioning cost estimate. The North Sea Transition Authority has challenged industry to reduce the cost of UKCS decommissioning by over 35% from the 2017 baseline estimate. It is widely acknowledged that rigless well abandonment techniques have potential to deliver considerable cost reduction through time savings, campaign work and the opportunity to utilise lower cost assets.

There is, however, a time-limited window of opportunity for development of the necessary intervention tools if rigless P&A is to have a meaningful impact on cost reduction. Cost and technical risk associated with trialling new technologies offshore is identified as an obstacle to securing the field trials needed to: refine the technology, achieve qualification required by operators, build a track record leading to deployment at scale.

This TLB Industry Sponsor Programme aims to harness a proven industry collaboration model between operators and supply chain to deliver opportunities for bulk field trials.

The Industry Lead Sponsor

Repsol Sinopec Resource UK was invited by the TLB to lead this programme in recognition of a demonstrated commitment to advance industry experience in Well Decommissioning through direct support of new technology development and active participation in other industry initiatives such as the Wells Task Force and OGUK. The company has identified Through Tubing technology development as a key enabler towards the application of rigless P&A to deliver cost saving and contribute to emissions reduction during well decommisioning.

Participation

The funding mechanism and governance principles required to deliver a multi-operator, multi technology programme will be similar to the Alternative Barrier Material ISP which has successfully secured bulk field trials in onshore wells in Canada. While the logistics and lower cost of access to land wells ensures more trials can be completed with the available funding, it is also hoped that access can be secured to run tools in a significant number of UK offshore wells.

Operators are being asked to provide the opportunity to run tools in their wells during conventional P&A programmes so the developers can acquire data and make direct comparison with conventional evaluation or verification methods. Useful data can also be acquired by providing access to run tools in wells as part of non-P&A intervention operations.

Repsol Sinopec and the Net Zero Technology Centre are providing initial funding support for the project, however, to sustain the programme over multiple years and secure testing for a number of evaluation and verification technologies, additional support from the UKCS operators will be required.

Documents and Publications