Alternative P&A Barrier

Materials Bulk Field Trials

OVERVIEW

The objective of this ISP programme is to deliver bulk field trials of alternative barrier materials for well P&A in a low cost environment to provide industry with the deployment and barrier verification data required to evaluate the field performance of the technology.

It is intended that this approach to support technology qualification will facilitate acceptance of the successful technologies by well operators and regulators.

Led by Spirit Energy, the programme is funded by consortia members including Spirit Energy, Harbour Energy and the Net Zero Technology Centre.

Alternative Barrier Materials

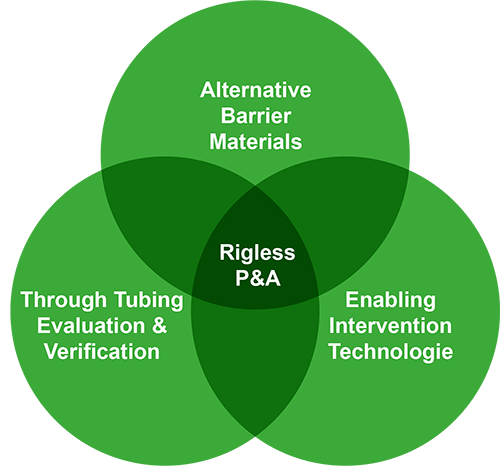

A range of new technologies are being developed which utilise the properties of a range of organic and inorganic materials as alternatives to Portland cement which has been traditionally employed in the construction P&A barriers. These alternative materials offer potential advantages over cement plugs in relation to a number of key barrier criteria including; impervious nature, deployment methodology (e.g. through tubing technology to support rigless P&A), control over placement and barrier formation, material stability and longevity; ability to interface with other barrier elements (e.g. formation, cement, casing/tubing). With well decommissioning activity in the UKCS ramping up, industry is focussed on qualification of these alternative barrier materials which creates a pressing need for access to wells for field trials.

Potential alternative barrier technologies

- Modified in situ materials

- Low melting point metal alloys

- Thermosetting Resins & Polymers

- Geopolymers

- Non-setting grouts

- Inorganic chemistry

- Advanced cements

The Challenge

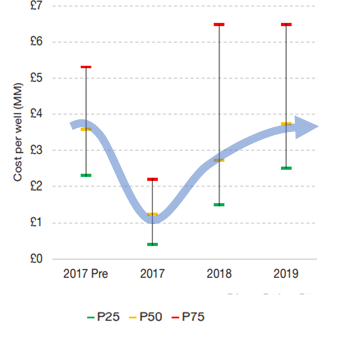

North Sea Transition Authority has challenged industry to reduce the cost estimate of UKCS decommissioning by over 35% from the 2017 baseline estimate. Well decommissioning accounts for circa 45% of the total basin cost estimate, providing a significant opportunity to help deliver the necessary cost reduction. It is widely acknowledged that alternatives to traditional cement based P&A approaches could increase the application of rig-less well abandonment techniques with potential for considerable cost savings. There is, however, a time-limited window of opportunity for these technologies to have a meaningful impact on cost reduction which necessitates the requirement to accelerate the transition between product development and commercialisation. High cost and technical risk associated with trialling new technologies offshore is identified as an obstacle to generating performance data, hindering the pace of development and leaving many operators reluctant to consider pursuing alternatives to cement.

The Solution

Field trials can be performed in land wells for significantly lower cost than offshore in the North Sea and with simplified logistics. This results in an increase in the number and pace of trials that can be delivered for the same level of funding. Using a collaborative funding model, well operators can reduce the individual cost of participation while securing access to trial data for a wider range of potential technical solutions.

In Alberta, Canada, the onshore well abandonment liability runs to several hundred thousand land wells with an estimated forty thousand of those exhibiting well integrity leaks resulting in sustained casing vent flow. This has created a pressing need to develop rig-less approaches to casing leak remediation as part of well decommissioning which is technically suited to alternative barrier material solutions and aligned with UK industry needs to reduce well abandonment costs. This provides the ideal opportunity for a collaborative approach between UK and Canadian industry to support technology developers utilise a lower cost environment to generate the volume of field trial data required by operators to qualify the solutions for inclusion in well decommissioning programmes and secure acceptance by the regulators of alternative approaches to P&A.

The Industry Lead Sponsor

Spirit Energy was invited to lead this programme by the TLB in recognition of their demonstrated commitment to advance industry experience of Alternative P&A Barrier technology through collaboration. Spirit (as former entity Centrica) participated in an earlier JIP to support development of a Thermite based barrier solution, providing access to wells in Canada, management and well engineering for field trials. Spirit subsequently completed the first onshore and offshore alternative barrier solution field trials working with the developer Interwell. The company has taken a prominent role in the workgroup preparing an update to the OGUK guidelines on P&A barrier material qualification and were a founding member of the Net Zero Technology and Alternate Barrier Collaboration Forum.

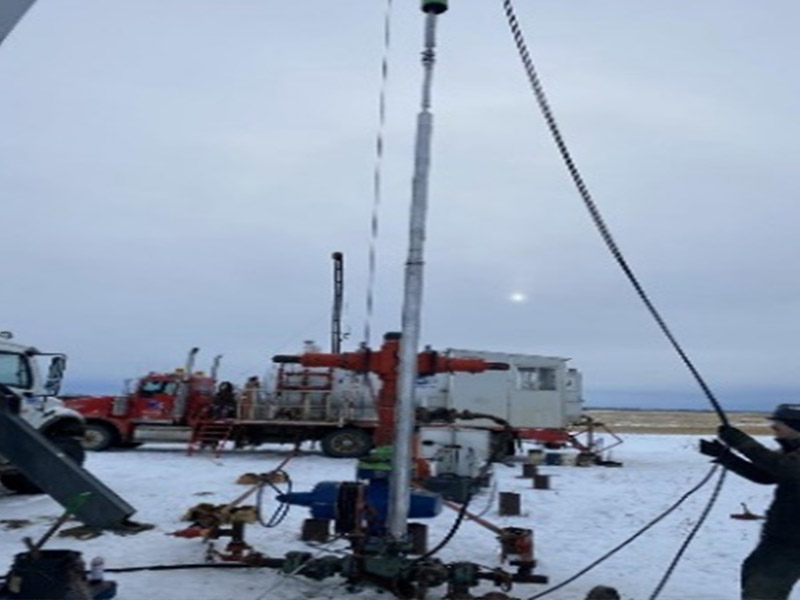

Rocksolid® field trial in Alberta – intervention mast at wellsite Photo courtesy of Interwell

The Programme

A steering committee formed by consortia members from the operators and funding bodies is responsible for selecting technologies to be tested. Subject to the field readiness of the technologies, it is hoped that the programme can support a continuous sequence of field trials. This will include qualification of solutions for regulator acceptance, intervention programme development, deployment and subsequent performance verification.

The technologies are currently being tested in “live” onshore wells made available by field operators in Alberta and British Columbia, Canada. It is hoped that testing can also be conducted in some UK land wells. It is intended to test up to 6 potential alternative barriers technologies under the programme and to fund 10 trials per year with 5 trials performed per technology. To allow testing in “live” wells, the technologies need to be deployment ready, typically meeting TRL 6 – 8.

In Canada, trial wells exhibiting Sustained Casing Vent Flow are selected to enable barrier solution performance to be verified more readily than would be the case for full well abandonment. Well programmes and acceptance of the barrier solution to be tested require approval by the State regulator ahead of the trial and verification of successful vent flow shut off also requires regulator approval. Whilst adding credibility to the trial results this also provides valuable experience of the interaction that operators and the UK regulators will be required to undertake if alternate barrier materials are to gain acceptance for field use in the North Sea.

Rocksolid® field trial in Alberta - trials need to be undertaken during the winter when the ground freezes at the wellsite allowing access Photo courtesy of Interwell

Rocksolid® field trial in Alberta – bear footprints at access road to the wellsite Photo courtesy of Interwell

ROADMAP

Please explore more by clicking on the graphic below

Progress

The first series of trials on Interwell’s RockSolid ® in situ modification thermite based solution is nearing completion with promising results that will enable the developer to take the next steps towards realising a commercial product suited to the North Sea.

Building on the work of previous industry support including field trials in the UK, Europe and Canada to develop the technology and completion of a test programme using mock-up and prototype tools, a qualification programme of five field trials have been completed in British Columbia and Alberta to shut off Sustained Casing Vent Flow from behind a single string of casing. The tool was successfully deployed in each case and a barrier to flow established. Performance of the barrier was verified in each case by monitoring for cessation of vent flow at the wellhead and tracking wellhead pressure decline over time as the gas inventory above the barrier dissipated. Sonic logging was subsequently performed to confirm that there was no in situ flow across the new barrier. The trials have been judged a success by the well operators and are being reviewed by the Alberta State oil and gas regulator (AER) in order to confirm the change in well status. Further details of the trial outcome will be communicated to the wider industry by publishing a case study.

Qualification of RockSolid ® for use in Canada to remediate SCVF will support technology transfer required to develop a product to meet the specific challenges of North Sea P&A applications.

Participation

The funding mechanism and governance principles required to deliver the programme have been demonstrated. The ability of UK and Canadian stakeholders to collaborate effectively has been proven with an increasing number of Canadian land well operators offering wells for field trial.

Funding has been identified to enable testing of a second technology to commence in 2022 and the steering committee are working on selecting the technology to trial. However, to sustain the programme over multiple years and increase the number of technologies tested, additional funding partners from the UKCS operators are required.